Kyntronics SMART Electro-Hydraulic Actuators (SHA) Compared to Hydraulic Actuation Systems (HPU)

Kyntronics SMART Electro-Hydraulic Linear Actuators (SHA) are an alternative to traditional hydraulic cylinders. The features and benefits of these two actuation technologies are compared below.

Discuss your application with an Engineer and learn how the all-electric, SMART Electro-Hydraulic Actuator (SHA) can eliminate hydraulics from your business, contact Kyntronics.

Contact an Engineer Size an Actuator Download PDF

Hydraulic Actuators / HPUs

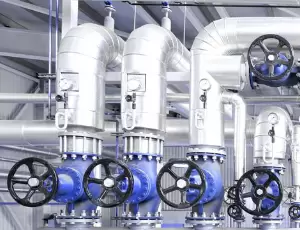

Hydraulic Actuators connected to Hydraulic Power Units (HPUs) are a commonly-used motion control solution. These systems are used in high force applications where robust performance is required.

Hydraulic actuators / HPUs require many components including:

- Pumps and motors

- Cylinders, hydraulic lines and fittings Fluid reservoir, accumulators and filters Servo control valves

- Electrical components / controls

- Pressure transducers and position sensors

- A significant volume of hydraulic fluid

Hydraulic Actuators are complex, high maintenance, expensive to operate and have a large footprint.

Hydraulic Actuators are complex, high maintenance, expensive to operate and have a large footprint.

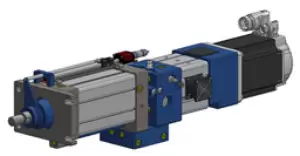

SMART Electro-Hydraulic Actuator (SHA)

The SHA is an all-electric, all-in-one, totally sealed, self-contained linear actuator consisting of a cylinder, pump, manifold and servo motor with optional drive/control system.

There are no hoses or leak points on the SHA vs. a traditional hydraulic cylinder / HPU system and the SHA contains minimal fluid (generally measured in ounces).

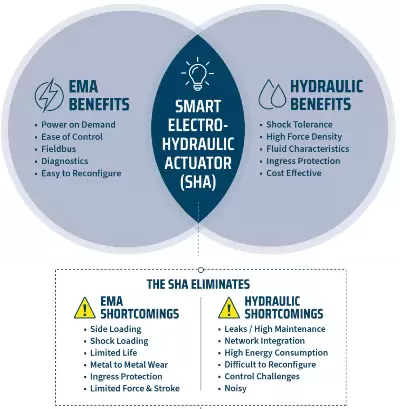

The SHA combines the Best Features of Screw-Type EMAs and Hydraulic Actuators while Eliminating their Shortcomings.

The SHA combines the Best Features of Screw-Type EMAs and Hydraulic Actuators while Eliminating their Shortcomings.

Feature and Benefit Comparison

Kyntronics SMART Electro-Hydraulic Actuator (SHA) vs. Hydraulic Cylinder / HPU

| Comparison Category | Kyntronics SHA | Hydraulic Cylinder / HPU | |

| Environmental Waste | The SHA is a totally-sealed system. Does not require fluid changes or replenishment. SHA Fluid volume measured in ounces for most applications. | HPUs require regular fluid changes and fluid replenishment which is expensive and creates environmental impact. | |

| Energy Usage | SHA uses power-on-demand to save energy. The All-In-One SHA design is more efficient by eliminating energy losses associated with hoses, connections and other components. | HPUs run constantly consuming significant amounts of energy. Hydraulic systems on average are 22% efficient due to energy losses from hoses, connections and other components. | |

| Maintenance Cost | SHA does not require regular maintenance other than a rod seal change (field replacement) after 50,000,000 inches of rod travel. | Hydraulic systems require regular maintenance including repair of fluid leaks, changing fluid, replacing filters and other components. | |

| Ergonomics / Safety | The totally-sealed design of the SHA eliminates leaks. SHA operates quietly and generates far less heat waste compared with HPUs. | Hydraulic system leaks create safety hazards that can result in lost-time accidents. Hydraulic systems are noisy and generate excessive heat due to inefficient operation. | |

| Unplanned Downtime / Product Spoilage | The sealed design of the SHA eliminates fluid contamination, often the cause of unplanned downtime, and eliminates the risk of fluid leaks that can spoil product and create scrap. | Fluid contamination is often the root cause of unplanned downtime. leaky hydraulics can contaminate products resulting in scrap and spoilage. | |

Annual Operating Cost Comparison

Kyntronics SMART Electro-Hydraulic Actuator (SHA) vs. Hydraulic Cylinder / HPU

| Comparison Category | SHA | HPU | Assumptions / Cost Basis (April 2023) | |

| Environmental Waste | $0 $0 | $33,600 $16,000 | 200 Gallon HPU Tank Hydraulic Fluid Index (HFI) = 4.1 SHA is sealed - no fluid replacement or disposal is required $42/gal x 800 gallons (4:1 HFI) $20/gal x 800 gallons (4:1 HFI) | |

| Energy Usage | $1,642 | $16,429 | SHA Uses Power on Demand SHA is 70% efficient (Kyntronics testing) 30 HP Hydraulic Power Unit that runs continuously HPU 22% is efficient (based on IFPE paper) Using $0.17 per KWh (average US rate - Fed 2023) | |

| Floor Space Utilization / Maintenance | $0 $1,760 | $2,000 $5,250 | SHA is All-in-One, no floor space required HPU requires space of 10'x10' = 100 Sq-ft @ $20 per sq-ft. SHA @ 1hr/week @ Labor $35/hr HPU @ 3hrs/week @ Labor $35/hr | |

| Ergonomics / Safety | $0 | $2,000 | HPU oil leaks create hazardous conditions and safety risk SHA is totally sealed, no oil leak risk Lost days + Medical costs + Legal costs | |

| Unplanned Downtime / Product Spoilage | $0 $0 | $10,000 $10,000 | SHA is totally sealed, no oil leak risk, minimal downtime risk $4k-$6k average downtime cost per incident. Assuming two downtime events. 1% scrap from product contamination due to leaky connections | |

| Annual Operating Costs | $3,392 | $95,279 | A $91,887 Annual Savings Opportunity! |

References

The basis for several of the assumptions used in the annual operating cost table originate from Fluid Power Industry published statistics and sources noted below:

- Hydraulic Oil Consumption – Measure to Manage

- Assessing Industrial Hydraulic System Efficiency

- Hydraulic System Leakage - The Destructive Drip

- Calculating the Cost of Downtime

To discuss your application with an Engineer and learn how the SMART Electro-Hydraulic Actuator (SHA) can help to eliminate hydraulics from your business, contact Kyntronics.