Kyntronics SMART Electro-Hydraulic Actuators (SHA) Compared to Electro-Mechanical Screw-Type Actuators (EMA)

Kyntronics SMART Electro-Hydraulic Linear Actuators (SHA) are a robust “electric” alternative to screw-type actuators. The features and benefits of these two actuation technologies are compared below.

Discuss your application with an Engineer and learn how the all-electric, SMART Electro-Hydraulic Actuator (SHA) can eliminate screw-type actuator reliability issues, contact Kyntronics.

Contact an Engineer Sizing an Actuator Download PDF

Ball Screw / Roller Screw Electro-Mechanical Actuators (EMA)

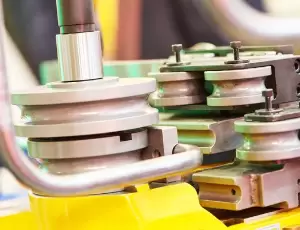

Ball Screw and Roller Screw actuators (EMAs) are a commonly-used linear motion solution. These systems are deployed where precision control is required and often as a replacement for hydraulic cylinders in some higher force applications.

Screw-Type actuators are susceptible to damage from shock loads and premature wear causing unplanned downtime and reliability issues.

Screw-Type actuators are susceptible to damage from shock loads and premature wear causing unplanned downtime and reliability issues.

Screw-Type EMA Challenges

- Gears, roller and ball screws and other mechanical components wear out from metal-to-metal contact from repetitive concentrated loads.

- Shock loads and Side loading can cause significant damage and premature failure.

- EMAs require regular lubrication and have a finite life (see L10 chart below).

- EMAs require expensive load cells for accurate force control.

- EMAs require a brake to hold position, can be back-driven and have backlash.

- Are large & very costly at higher loads (>5,000lbf).

- Have limited stroke length (24”) without incurring expensive premiums.

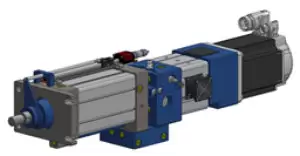

SMART Electro-Hydraulic Actuator (SHA)

The SHA is an “electric linear actuator” that looks similar to a screw-type actuator but rather than using gears, drive screws and driven nuts, the all-in-one SHA uses an integral hydraulic cylinder with minimal amount of fluid and no hoses or leak points.

The SHA combines the Best Features of Screw-Type EMAs and Hydraulic Actuators while Eliminating their Shortcomings

The SHA combines the Best Features of Screw-Type EMAs and Hydraulic Actuators while Eliminating their Shortcomings

Actuator Reliability Comparison

Kyntronics SMART Electro-Hydraulic Actuator (SHA) vs Electro-Mechanical Ball Screw / Roller Screw Actuator (EMA)

Ball Screw Actuator

Roller Screw Actuator

Kyntronics SMART Electro-Hydraulic Actuator (SHA)

Electro-Mechanical Actuator (EMA)

- EMA life span is load dependent. Improving EMA life requires larger and more expensive size screws

- EMA metal-to-metal wear further decreases reliability and requires regular lubrication

- EMAs are highly susceptible to damage from shock loads and side-loading

Kyntronics SMART Electro-Hydraulic Actuator (SHA)

- SHA is rated at 50,000,000 inches of travel (before a simple rod seal change) regardless of load

- No metal-to-metal contact leads to increased reliability (load independent)

- The SHA provides 10X-100X better reliability compared with Ball Screw / Roller Screw Actuators

Cost Comparison at Different Force Ratings

Kyntronics SMART Electro-Hydraulic Actuator (SHA) vs Electro-Mechanical Roller Screw Actuator (EMA)

Roller Screw EMA

Kyntronics All-in-One SMART Electro-Hydraulic Actuator

Cost Assumptions

- Includes Actuator, Servo Motor, Servo Drive

- 24" Stoke Length, add 15% Premium to Roller Screw if longer

- Standard Configuration, Standard L10 Roller Screw Life

- Cost Amounts are Approximate Distributor Net Cost

The SHA is available in many flexible configurations unlike screw-type EMAs

Parallel Standard

Parallel Standard Parallel with Spacer Block

Parallel with Spacer Block 90° Centered

90° Centered Parallel Inverted

Parallel Inverted Inline

Inline 90° Behind Power Unit

90° Behind Power Unit

To discuss your application with an Engineer and learn how the SMART Electro-Hydraulic Actuator (SHA) can help to eliminate hydraulics from your business, contact Kyntronics.