Process Control

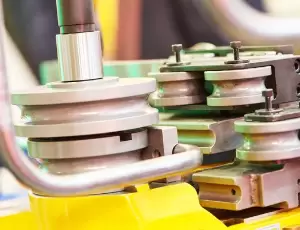

Actuation Systems for Process Control

Kyntronics all-electric, all-in-one SMART Electro-Hydraulic Actuators are ideal for Process Control applications requiring high force, long stroke, shock load tolerance, higher IP ratings and robust performance.

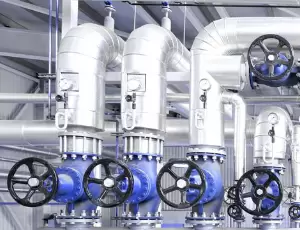

Kyntronics actuators are used in many demanding Process Control applications including:

Products – SMART Electro-Hydraulic Actuator (SHA); S-Series, E-Series and Servo Power Units (SPU).

Kyntronics Actuator Benefits for Process Control Applications:

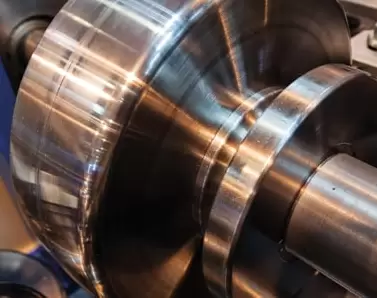

- High force in a compact package. Up to 150,000 LBs force (665kN)

- All-electric, all-in-one solution, eliminates the need for hydraulic infrastructure, reducing cost and maintenance

- Servo precision control of position, speed and force , high-speed, smooth motion

- Highly tolerant of shock loads and concentrated loading

- Manual Override Options

- Power On-demand, energy efficient

- Rugged design, very reliable

- Programmable & flexible

- Fieldbus compatible control interface

Learn about the advantages of our SMART Electro-Hydraulic Actuators